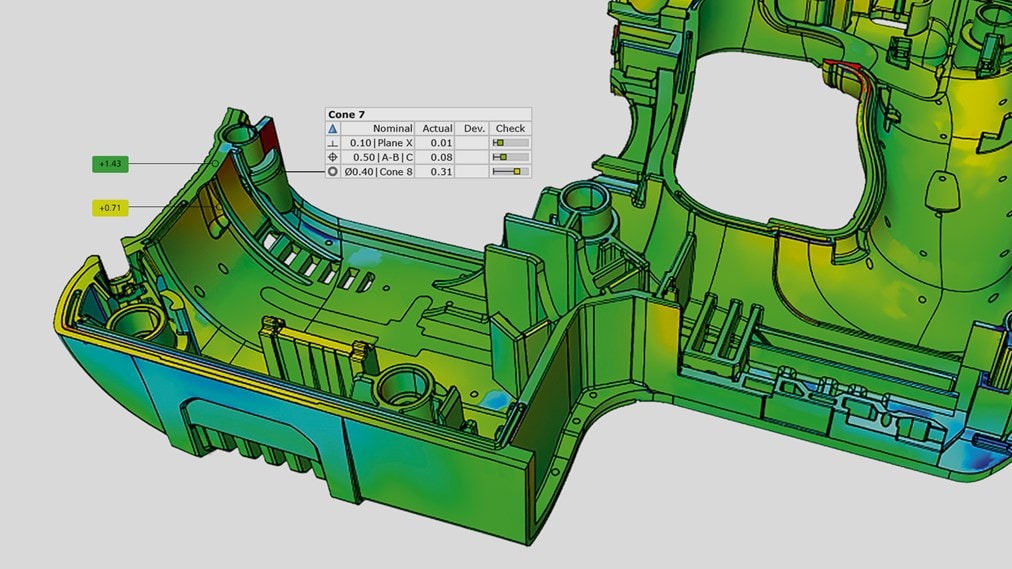

ZEISS INSPECT is a 3D metrology software for analyzing 3D measuring data from fringe projection or laser scanners, coordinate measurement machines (CMM) and other measuring systems. The ZISS Inspect software is used in product development, quality control and production.

- If the CAD or single elements change, the measurement positions are automatically updated with “Smart Teach”. In addition, the user is much more supported in achieving a stable measuring sequence in a shorter time by advanced display options of the project status. This is also further emphasized by the introduction of scanning templates for setting application-specific parameters prior to the measuring procedure. For complex or shiny surfaces that require a specific measuring angle, these improvements lead to a significant increase in efficiency.

- If a defect is detected by several tools, the found defects can be merged into one representation. This means that the audit score no longer depends on the number of tools used, but on the quality of the part. In addition, the new software offers the possibility of testing a part against a limit sample. This enables a simple actual-actual comparison, and known, accepted defects are not displayed in the result representation. With advanced functions for the defect analysis, there is now also a convenient way to find and analyze skid lines, expanding the application range of this solution.

With a new module that supplements the ATOS and ZEISS INSPECT Professional software packages, sheet metal and injection-molded parts can be virtually clamped and thus measured without complex clamping devices. An innovative, FEM-based algorithm makes it possible to compute the constrained state of the part. This virtual clamping procedure is fully integrated into the GOM workflow; there is no need to leave the software interface.