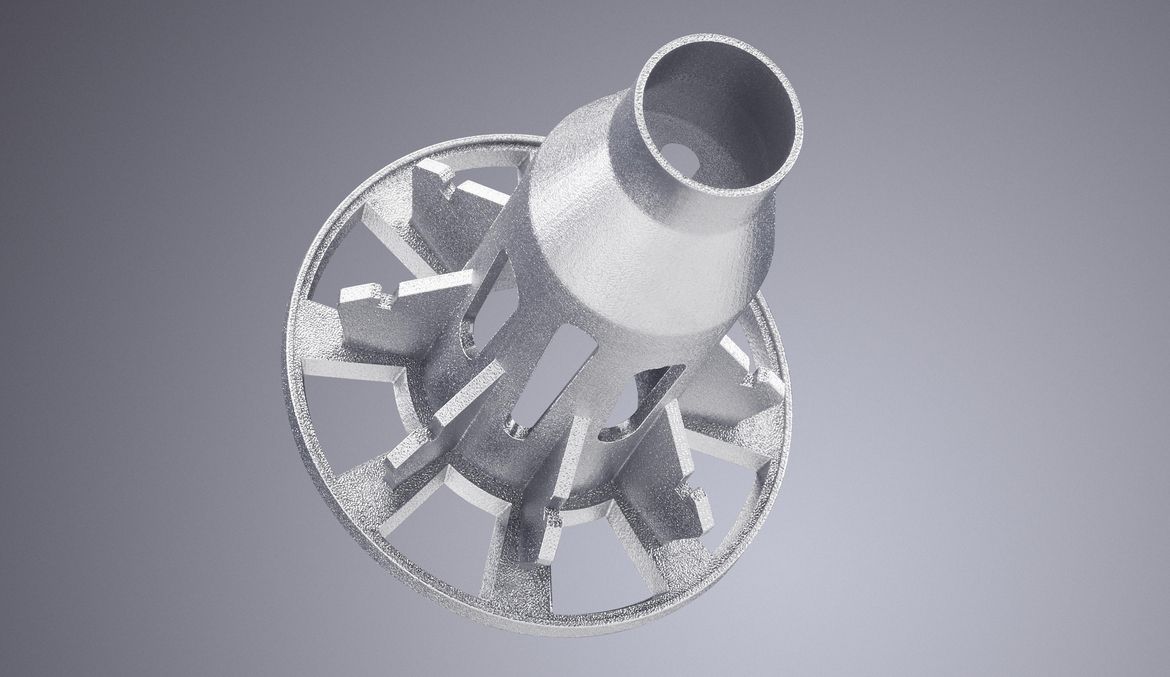

The TruPrint 1000 is the most productive machine in compact form and offers you all the benefits of additive manufacturing. The build volume (cylinder) is 100 mm in diameter and a height of 100 mm. This can be reduced for precious metals. The TruPrint 1000 can be used to create components in almost any geometric shape. Even relatively complex shapes can be quickly and easily converted from the CAD design to a 3D metallic component – with top quality.

- Thanks to the Multiplate option, you benefit from a longer machine runtime for the TruPrint 1000. It can accommodate up to four substrate plates in the build cylinder, which change automatically without stopping the LMF process.

With the TruPrint 1000, TRUMPF offers the most productive 3D printer for the dental sector to date for the creation of dental prostheses. There’s even more: your digital connection with milling stations is another highlight. This facilitates new and highly precise dental products.