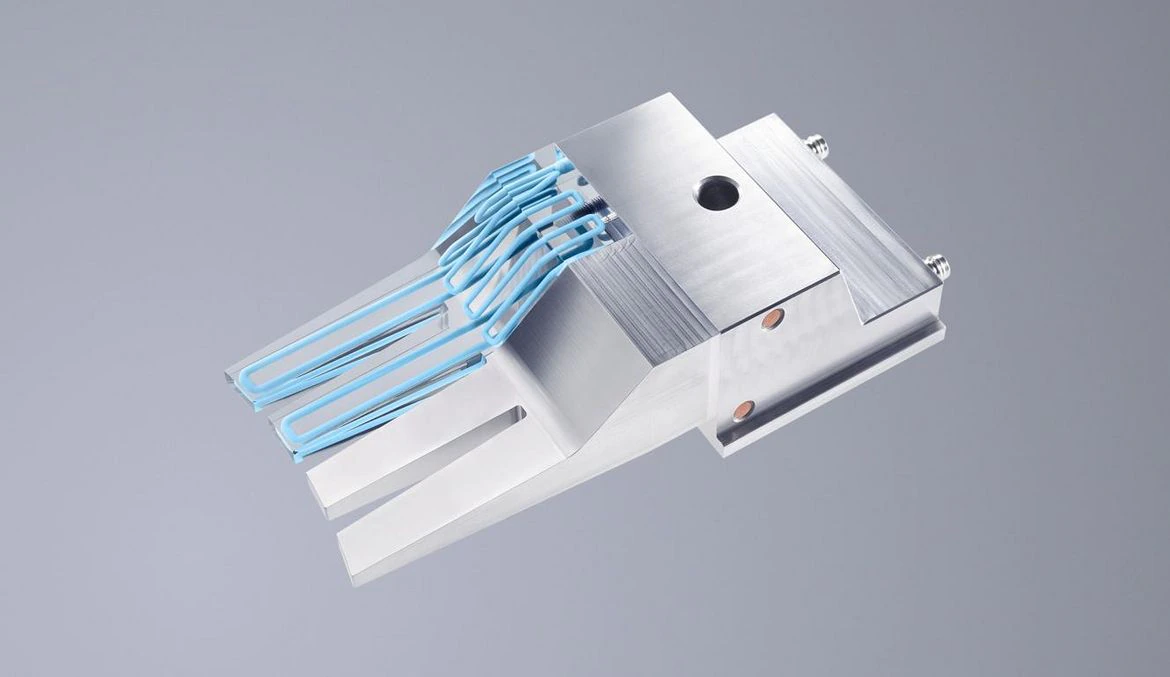

The highly productive, partially automated TruPrint 5000 3D printing system provides the ideal basis for industrial series production. With optional features, including 500°C-preheating and the fullfield multilaser with three 500-watt TRUMPF fiber lasers, you are perfectly equipped to handle even the most demanding industrial applications.

- Combined with external part and powder management and the monitoring solutions from TRUMPF, it is predestined for industrial additive series production.