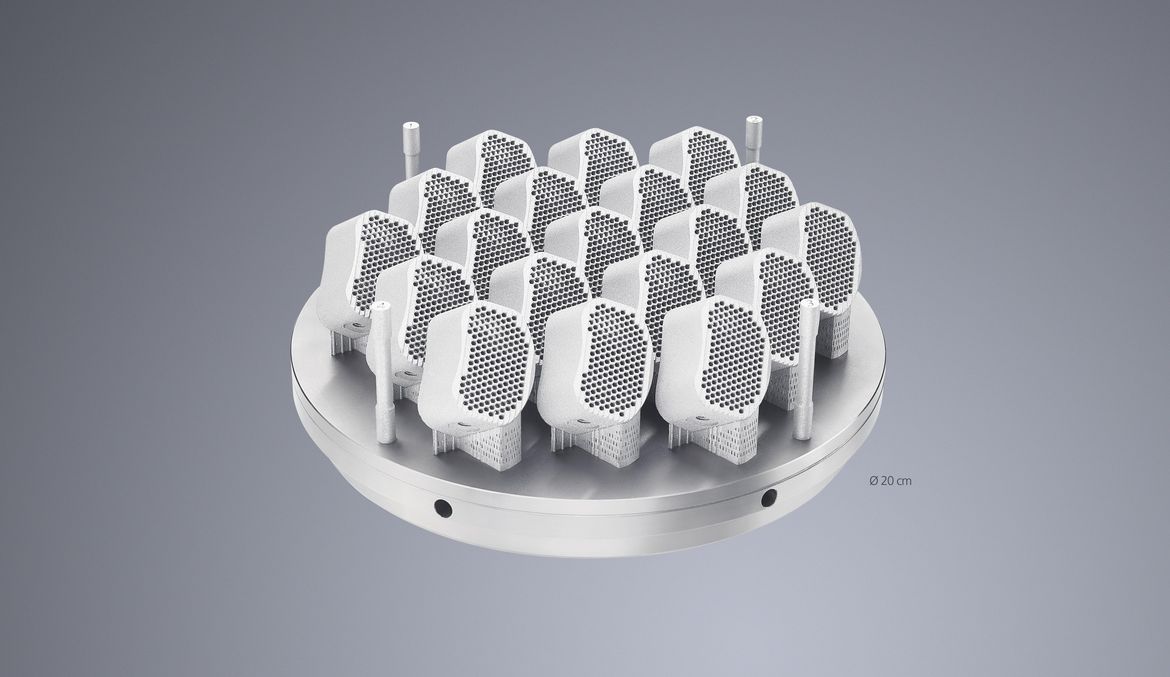

With its small 55-µm laser beam diameter, the TruPrint 2000 provides a high-quality printing result which impresses with its surface quality and level of detail. It offers a build volume (cylinder) of 200 mm in diameter and a height of 200 mm. The fullfield multilaser with two 300-watt fiber lasers from TRUMPF – which scan the entire build area – delivers top productivity.

Melt Pool Monitoring and comprehensive process monitoring ensure the highest quality standards. The production process with the TruPrint 2000 is a closed powder circuit under shielding gas. This allows for easy and practical handling, with the highest operator safety.