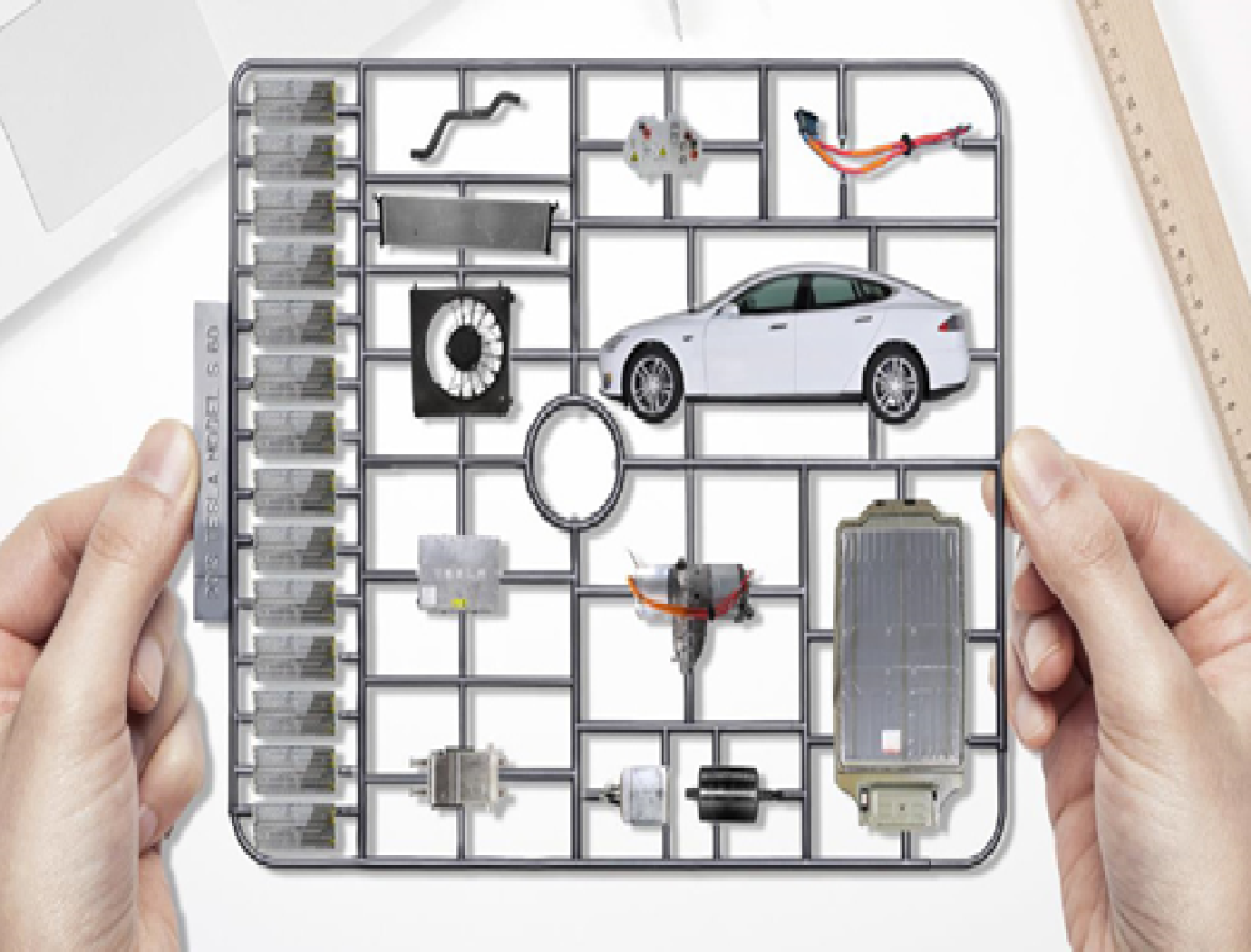

Overview: We were approached by a leading manufacturing company in the automotive Industry. This company has been in the business of manufacturing automobiles for one of the longest times in history. They have also always satisfied their customer and made sure that the customer comes first always. They have also with complete integrity delivered the best products the most reasonable price. They had a project that carried great value and it was a pleasure carrying out the project. The requirement of the company was for 3D scanning and modelling service to which we were able to deliver with utmost efficiency. The project so entered between us required a high level of accuracy and experience. We were to achieve the scanning process by using 3 different vehicles for this project.

- Challenge & Solution: This project involved the scanning of heavy machinery beyond the normal sizes. The client had an intention of acquiring specifically the wielding details, the number of parts, machining parts, sealing details, benchmarking. The process benchmarking process required immense amount of detailing of intricate parts and the most minute details had to be jotted down in order to document the process for further improvements. The process also involved weighing each part before and after disassembling and breaking down. The specification sheets were provided.

- Explicit solution: The dismantling process for the 3 vehicles was a task that proved to be worth the effort. The scanning of BAW required highly skilled and experienced personnel. Segment by segment scanning had to be performed and the thick metal sheets of the vehicles had to be cut into separate parts in order to ensure scanning with the highest level of accuracy. There was no room for any error. The detailing of modelling each vehicle had to be accurate down to the most minute of detail. Avoiding layering and noise was a challenge that was successfully overcome. Overlap of quantity data was one such other challenge which was triumphed. Setting the right point spacing was one of the crucial aspects of the project.

Thus after the successful completion of the project the client was more than happy to extend the period and scope of the project to Tensile testing.

Get a Quote

Upload your Part

Upload your part for an instant quote.

Get a quote

Experts are working on your quote, will be generated within 24 hours.

Ship your part to us

Ship your part to us, and we’ll work on it right away.