GOM’s optical 3D measuring systems are integral to the sheet metal forming process chains, including stamping, bending, drawing, pressing, and forming, ensuring consistent quality assurance. These systems are used to determine material properties, optimize the design and simulation of parts and tools, and accelerate tool try-out and first article inspection. Additionally, optical 3D measuring systems enhance production control and assembly analysis in series manufacturing.

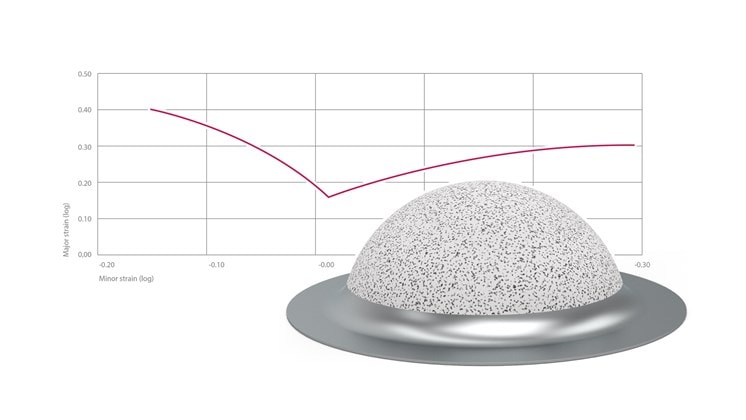

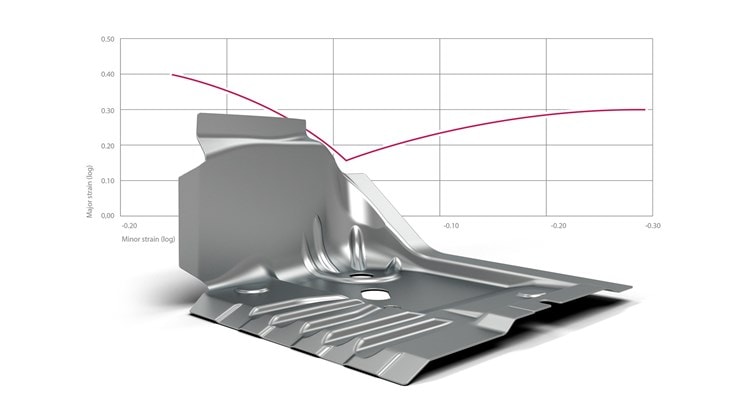

Material properties

The knowledge of material properties of a sheet metal material provides a secure basis for adequate component design, for developing a functioning tool with good effective surfaces and for realistic simulation.

Realistic material properties are a prerequisite for reliable simulation and optimization of product variants, tool layout and forming processes.

Design

3D digitization helps to quickly generate and efficiently use CAD data.

Actual 3D coordinates enable reverse engineering of models, parts and tools. For that, the 3D geometry of these objects is fully scanned and then transferred into CAD data via surface reconstruction.

The inspection of parts can be carried out efficiently. During design, the CAD data is directly provided with inspection features. As soon as a part is produced, it can be inspected immediately.

Simulation

Products and manufacturing processes are designed and optimized with numerical simulation methods. The results of these simulations are supposed to be as informative as possible.

An important factor for the simulation of metal forming processes are the material properties of the metal used. The material properties influence the deformation behavior of the part and therefore the accuracy of the simulation calculation.