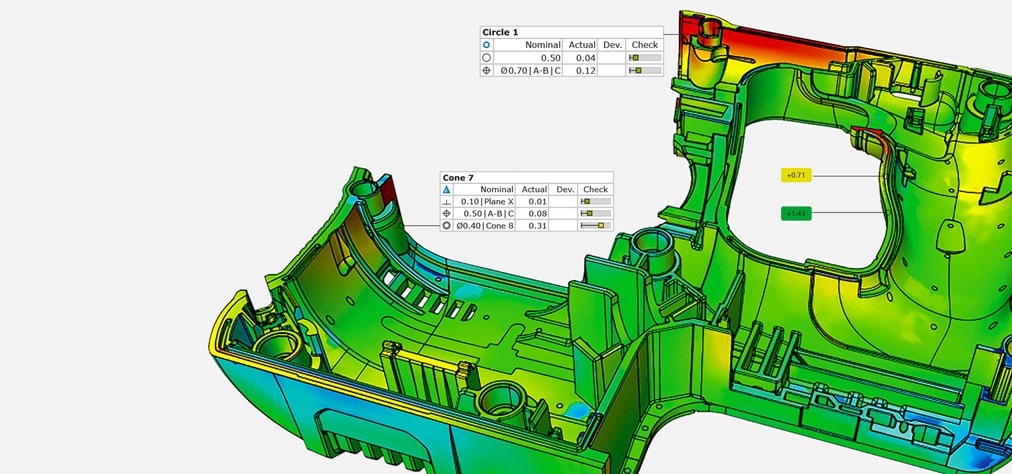

Short product cycles, cost pressure and high quality requirements force manufacturers of consumer goods to develop and produce products efficiently. Therefore, GOM systems are used for all production processes—ranging from design and materials testing through tool and mold making, first article inspection and production up to assembly analysis and load tests. During the tool buy-off and first article inspection, full-field measuring results provide comprehensive data about geometric and dimensional accuracy of the manufactured parts. In this way, start-up periods for product launches can be reduced significantly.

Applications and Benefits

- Professional software and hardware form a powerful engineering tool

- Improved product development

- Complete part inspection

- Tolerance visualization in color plot

- Prototype analysis with digital assembly

- Tooling inspection and root cause analysis

- Reverse engineering and virtual reality rendering

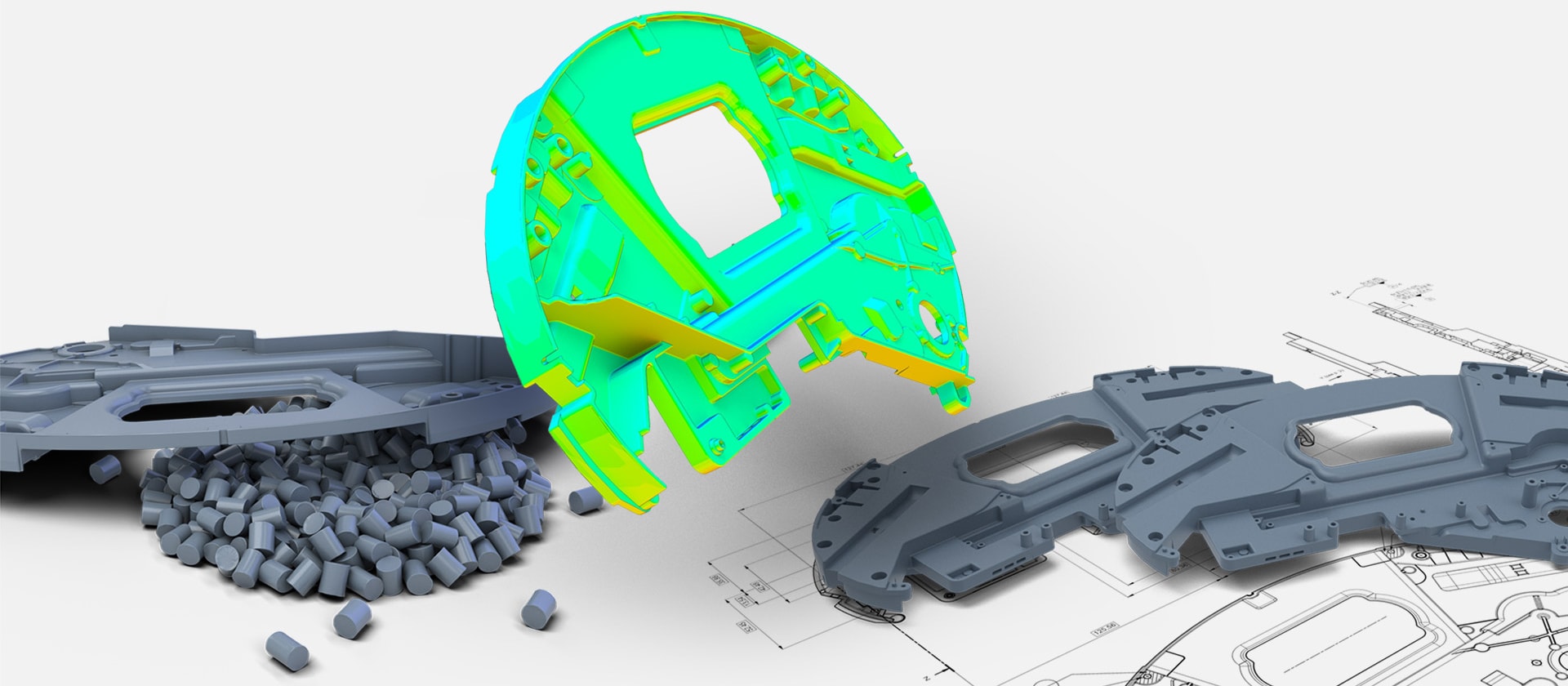

3D Metrology Applications in the Plastics Manufacturing Process

In plastics engineering, 3D measurement technology supports and speeds up all phases in injection molding, blow molding and thermoforming processes: from prototype and tool construction to first article inspection reports up to assembly analysis and load testing.

Quality Assurance of Plastic Parts with Optical 3D Measurement

The product portfolio of the Procter & Gamble subsidiary Braun includes electric razors, epilators and hair and dental care appliances under well-known brands such as Gillette and Oral-B. Braun has already taken numerous prizes for the design of its high-quality products and gives priority to precision and dimensional accuracy during manufacturing.