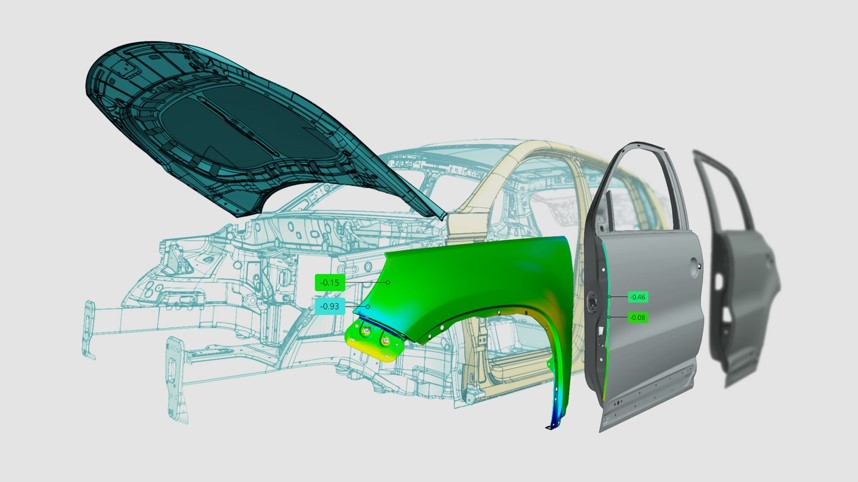

In the automotive industry, GOM systems are used throughout the entire development process of a new automobile. In product development, measuring data provides information about material characteristics and part behavior. The results influence simulation and engineering. In production quality control, which is becoming increasingly automated, the full-field geometry acquisition by 3D scanning provides the data basis to inspect forms and tools, cast parts, plastic and sheet metal parts as well as assemblies and complete car bodies.

Development and Prototyping

The development cycle of a new car model involves many steps and departments and takes up several years until the final start of production. 3D metrology systems are used for many different applications during this development phase.

Series Production

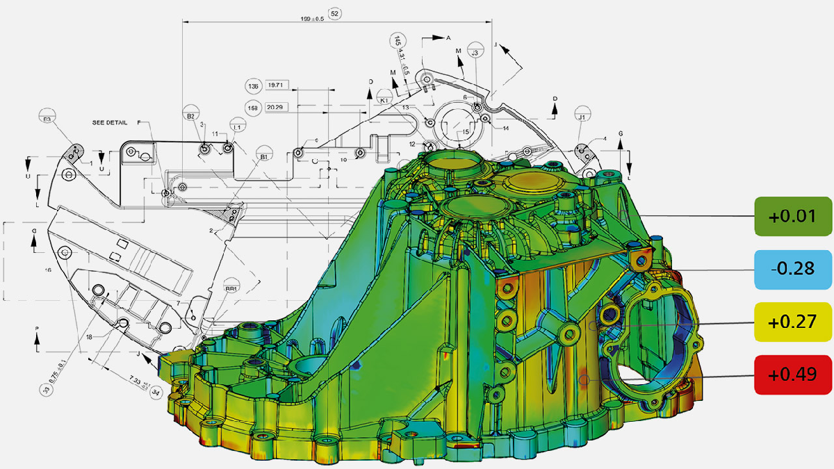

After designing a car and its components, and once all materials have been selected and all tools, dies and molds are finished, the car can finally go into series production. Quality management and assurance are steadily gaining importance in industrial development and manufacturing.

Manufacturing Processes

Optical measuring systems are used in all manufacturing processes. Quality assurance and process optimization can be supported by 3D data throughout the complete process chain for sheet metal parts, plastics or cast parts. Furthermore, 3D data gains more and more importance through new additive manufacturing applications and trends.