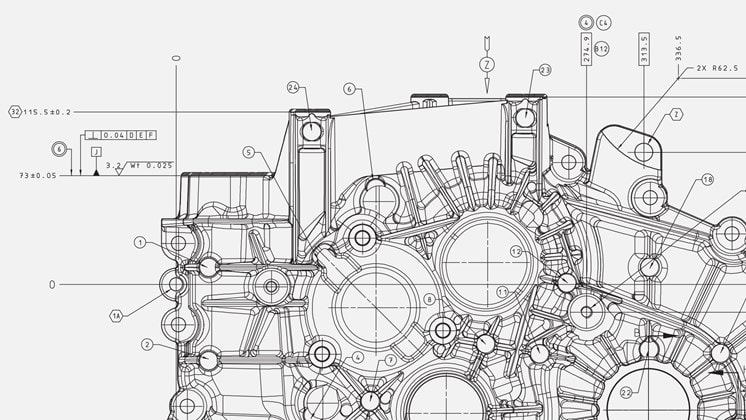

GD&T tolerances allow for determining and assessing geometrical deviations of parts. They describe the maximum permissible deviations from the nominal state of a part. If GD&T tolerances are exceeded, the function, accuracy of fit or form of the part is not fulfilled. The tolerances can be used to determine whether a bore hole is manufactured to fit exactly, whether it has the correct direction or whether existing form errors are within the permissible limits, for example. GD&T tolerances are used throughout all steps of the process chain, such as design, production and quality control.

Possible causes for GD&T deviations are, for example:

- Deformation during processing

- Wear and tear of the tool

- Machine vibration

- Temperature fluctuations during processing