INDUSTRIES WE SERVE

A Team with over 25 years of cumulative engineering experience and Expertise

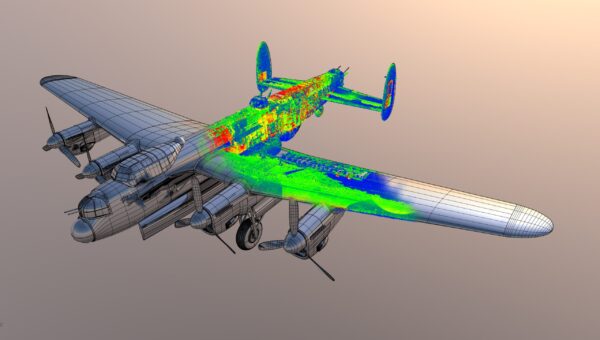

Aerospace

GOM systems support the aerospace industry and its suppliers by providing precise part geometries and deformation analysis. This data is used in R&D, Manufacturing and MRO to understand failure modes and ensuring proper quality and overall safety of the aircraft. By building a full Digital Twin of the aircraft and its systems, the GOM optical metrology sensors, coupled with powerful analysis software, help the aviation industry build and maintain aircraft faster and safer…,

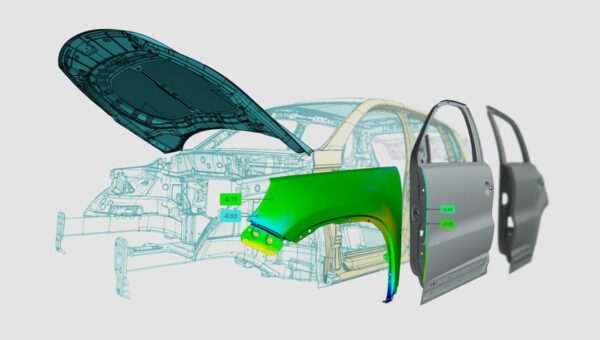

Automotive

In the automotive industry, GOM systems are used throughout the entire development process of a new automobile. In product development, measuring data provides information about material characteristics and part behavior. The results influence simulation and engineering. In production quality control, which is becoming increasingly automated, the full-field geometry acquisition by 3D scanning provides the data basis to inspect forms and tools, cast parts, plastic and….,

Casting Foundry

Measuring systems from GOM are used in sand, pressure die and investment casting processes to guarantee consistent quality assurance: from simulation validation via accelerating tool try-out and first article inspection up to production control and CNC machining. GOM systems allow for inspection planning based on design data. In pattern and mold making, the targeted correction of tools and models and the inspection of fitting of mold halves, cores and sliders are possible…,

Consumer Goods

Short product cycles, cost pressure and high quality requirements force manufacturers of consumer goods to develop and produce products efficiently. Therefore, GOM systems are used for all production processes—ranging from design and materials testing through tool and mold making, first article inspection and production up to assembly analysis and load tests. During the tool buy-off and first article inspection full-field measuring results provide comprehensive data about…,

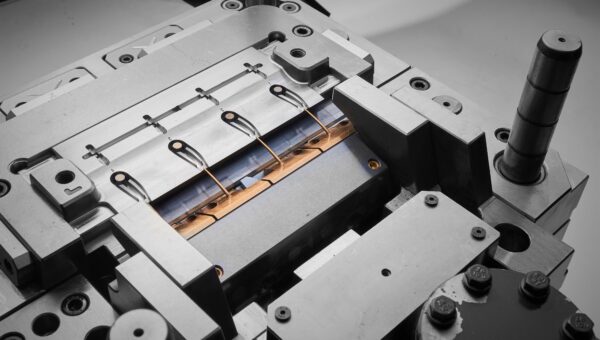

Injection Molding

In plastics engineering, 3D measurement technology supports and speeds up all phases in injection molding, blow molding and thermoforming processes: from prototype and tool construction to first article inspection reports up to assembly analysis and load testing. ATOS is an optical 3D coordinate measuring system allowing non-contact measurements of complete surfaces of prototypes, electrodes, tools and injection-molded parts regardless of the object size…,

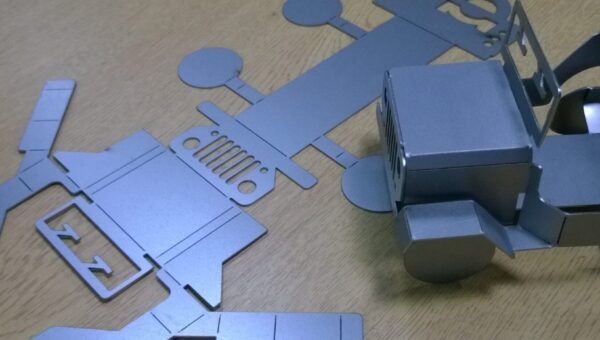

Sheet Metal Forming

GOM’s optical 3D measuring systems are used in stamping, bending, drawing, pressing, and forming process chains to guarantee consistent quality assurance: They are used to determine material properties. They help to optimize the design and the simulation of parts and tools. They speed up tool try-out and first article inspection. Optical 3D measuring systems also ensure efficient production control and assembly analysis in series…,