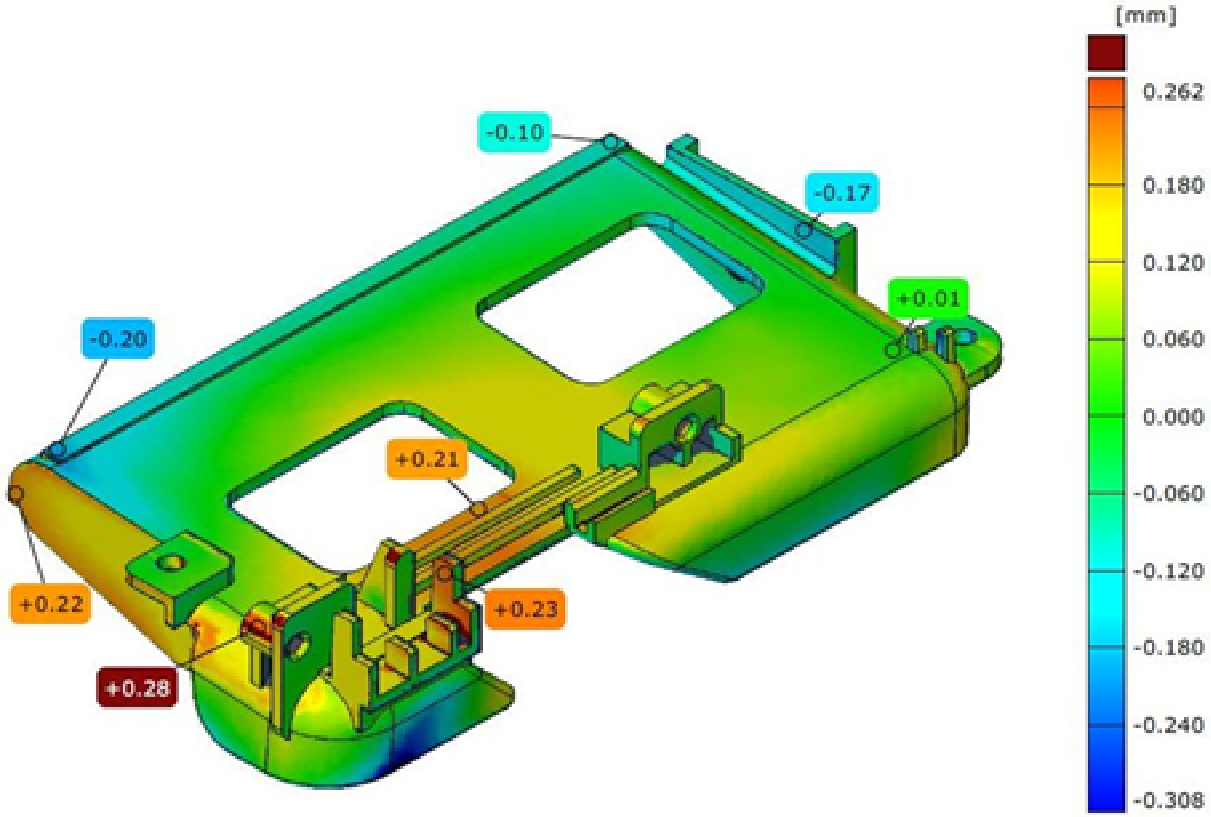

The process of comparing 3D data against a CAD model is referred to as CAD-Compare, and can be a useful technique for applications such as determining wear patterns on molds and tooling, determining accuracy of final build, analyzing gap and flush, or analyzing highly complex sculpted surfaces.

Industrial processes such as assembly are complex, highly automated and typically based on CAD data. The optimal performance of this process is guaranteed by quality assurance systems. Especially the geometry of the metal parts must be checked in order to assure that they have the correct dimensions, fit together and finally work reliably.quality 3D data suitable for high precision machined parts of various industries.

Within highly automated processes, the resulting geometric measures are transferred to machines that manufacture the desired objects. Due to mechanical uncertainties, the result may differ from its digital nominal (CAD). In order to automatically capture and evaluate these deviations, the manufactured part must be digitized as well. For this purpose, 3D scanners are applied to generate point samples from the object’s surface which are finally compared against the nominal data.